The Transformative Power of China Prototyping Manufacturing

In today’s fast-paced and ever-evolving market, businesses are constantly on the lookout for innovative solutions to optimize their production processes. One term that has gained significant traction over the past decade is "China prototyping manufacturing." This approach not only speeds up product development timelines but also enhances the quality and reduces the costs associated with manufacturing. In this article, we will delve deeply into the various facets of prototyping manufacturing in China and how it can significantly impact your business.

Understanding Prototyping Manufacturing

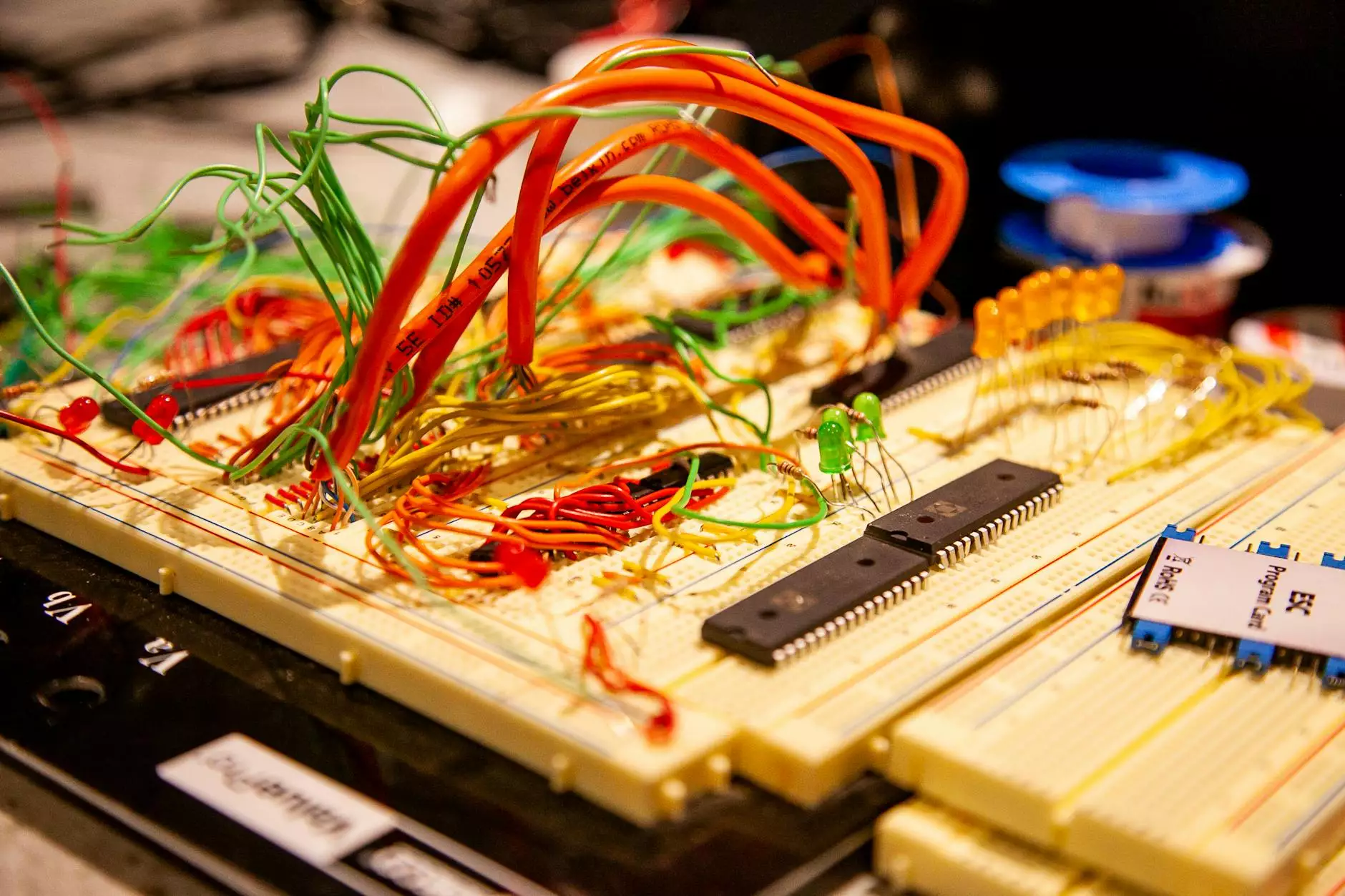

Prototyping is a critical phase in the product development cycle, allowing designers and engineers to create tangible models of their ideas. China prototyping manufacturing has emerged as a leading choice for companies around the globe due to its advanced technology, skilled labor, and competitive pricing. Let’s explore some of the key aspects that make this manufacturing technique so beneficial.

Advantages of Prototyping Manufacturing

Implementing prototyping manufacturing offers several substantial advantages, including:

- Rapid Turnaround: Prototyping manufacturing in China enables businesses to quickly create prototypes, facilitating faster product development and testing.

- Cost-Effectiveness: Reduced labor and production costs in China allow for higher profitability margins while maintaining quality standards.

- Advanced Technology: Access to state-of-the-art manufacturing technologies, including CNC machining, 3D printing, and injection molding.

- Versatile Material Options: A wide range of materials is available for prototyping, from plastics to metals, accommodating various industrial needs.

- Skilled Workforce: China boasts a vast pool of skilled labor adept at utilizing advanced manufacturing processes.

The Role of Metal Fabricators in China Prototyping Manufacturing

Metal fabricators play a pivotal role in China prototyping manufacturing. They specialize in the manipulation and assembly of metal components, ensuring high-quality products. Here’s how metal fabrication contributes to the overall process:

1. Precision Engineering

Metal fabricators apply precision engineering techniques to ensure that every component of a prototype meets exact specifications. This attention to detail is crucial for performance and durability.

2. Customization

With advancements in manufacturing technologies, fabricators can create highly customized prototypes that cater to specific business requirements. This flexibility is especially beneficial in industries such as automotive, aerospace, and electronics where unique specifications are a norm.

3. Material Selection

Metal fabricators are knowledgeable about different metal types, enabling businesses to choose the most appropriate materials for their prototypes based on strength, weight, and cost.

How to Choose the Right Manufacturing Partner in China

Finding the right partner for your china prototyping manufacturing needs can be daunting, but with these key considerations, you can make an informed decision:

1. Experience and Expertise

Look for a manufacturer with a proven track record in your industry. Experience with similar projects ensures they understand the nuances and challenges you may face.

2. Technology and Equipment

Evaluate the technology and equipment the manufacturer uses. Modern machinery and techniques can greatly affect the quality and efficiency of your prototypes.

3. Quality Control Measures

Choose a partner that employs rigorous quality control measures throughout the manufacturing process to guarantee high standards in all outputs.

4. Communication and Collaboration

Effective communication is vital. Your manufacturing partner should be responsive and willing to collaborate with you throughout the prototyping process.

5. Cost Efficiency

While cost shouldn't be the only factor, it plays an essential role in determining the viability of a partnership. Ensure you find a balance between quality and affordability.

Case Studies: Success Stories in China Prototyping Manufacturing

Many companies have successfully utilized china prototyping manufacturing to launch innovative products. Here are a few notable case studies:

1. Automotive Innovations

Automobile manufacturers have leveraged Chinese prototyping capabilities to develop cutting-edge vehicle designs. The rapid prototyping processes allowed them to test multiple design iterations quickly, ensuring performance and safety meet international standards while keeping costs down.

2. Consumer Electronics

Leading tech companies have turned to Chinese manufacturers for their prototyping needs. By effectively utilizing prototyping facilities, they brought products to market faster while maintaining high quality, ultimately leading to a competitive edge in the fast-paced electronics market.

3. Aerospace Advancements

The aerospace industry has benefited from China's prototyping capabilities to explore new designs and materials. Prototypes developed in China have undergone extensive testing, leading to significant advances in aircraft technology.

Future Trends in Prototyping Manufacturing

The landscape of prototyping manufacturing is continuously evolving. Here are some predicted trends that may shape the future:

1. Increased Use of Automation

As technologies advance, more automated processes will be incorporated into prototyping manufacturing, enhancing efficiency and precision.

2. Sustainability Practices

With growing environmental concerns, manufacturers are exploring sustainable materials and production techniques, reducing waste and carbon footprint.

3. Integration of Artificial Intelligence

AI algorithms are expected to play a larger role in design optimization and quality control, ensuring fewer errors and faster turnaround times.

4. 3D Printing Dominance

3D printing technology will continue to gain popularity in rapid prototyping, allowing for complex designs and materials that are not feasible with traditional manufacturing methods.

Conclusion: Harnessing the Power of China Prototyping Manufacturing

In conclusion, China prototyping manufacturing presents an incredible opportunity for businesses looking to innovate and stay ahead of the competition. With its myriad of advantages—such as cost-effectiveness, rapid turnaround, and a skilled workforce—utilizing this approach can significantly enhance product development processes. By strategically choosing the right manufacturing partner, companies can maximize their prototyping capabilities and pave the way for future successes.

For businesses seeking to elevate their products through expert metal fabrication, look no further than DeepMould.net. With a dedication to quality and innovation, DeepMould is poised to help you bring your ideas to life with excellence.